RoofCont provides expert roofing, siding and contractor services, specializing in installations, repairs, and replacements for residential and commercial properties.

RoofCont provides expert roofing, siding and contractor services, specializing in installations, repairs, and replacements for residential and commercial properties.

Industrial roofs protect buildings from harsh weather. They face rain, wind, snow, and heat daily. Over time, this constant exposure causes damage. Cracks, leaks, and wear reduce their strength. Without proper care, roofs lose efficiency. That’s why strong industrial roof fixtures matter. They support durability and safety. Quality materials prevent early damage. Proper installation boosts performance. Regular maintenance extends lifespan. Ignoring roof issues leads to costly repairs. Strong fixtures handle extreme conditions.

They resist moisture, heat, and impact. Choosing the right fixtures ensures long-term protection. Industrial buildings need reliable roofing solutions. Always focus on high-quality materials. A well-maintained roof improves safety. Protect your building with the best fixtures. Industrial roof fixtures explained in simple terms help businesses stay secure.

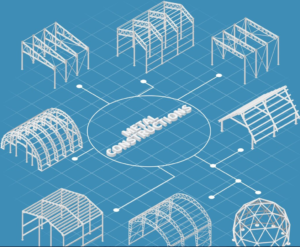

Industrial roof fixtures explained, metal roofing lasts long and resists fire. Built-up roofing uses tar and gravel for strength. Single-ply roofing offers quick installation. Green roofs add plants for insulation. Thermoplastic roofs handle extreme weather.Here are some common types of industrial roofing systems. See detailed information about each one of them.

TPO roofing is a strong and flexible option. It protects buildings from heat, UV rays, and chemicals. Many industries use TPO for its energy-saving benefits. It reflects sunlight, reducing cooling costs. In the U.S., over 40% of commercial buildings use TPO.

This roofing lasts 20 to 30 years with proper care. Strong seams prevent leaks and water damage. It resists mold, dirt, and punctures. TPO works well in hot and cold climates. Installation is quick and cost-effective.

It requires low maintenance, saving businesses money. Roofers use heat to seal seams, creating a waterproof layer. This increases durability and strength. Many factories, warehouses, and offices choose TPO. It meets U.S. energy standards for efficiency. Industrial roof fixtures explained in detail help businesses select the right roofing. Durable materials improve safety and performance. Always choose quality fixtures for long-lasting protection.

Metal roofs offer strength and durability. Many industrial buildings use metal for long-term protection. Steel, aluminum, and copper are common choices. These materials resist fire, wind, and heavy rain. In the U.S., over 50% of industrial buildings have metal roofs.

They last 40 to 70 years with proper care. Metal reflects heat, reducing cooling costs by 25%. It works well in all climates. Factories, warehouses, and commercial buildings benefit from its strength. Coatings prevent rust and corrosion. Strong panels block leaks and moisture damage. Roofers install metal sheets in large sections.

This speeds up installation and lowers labor costs. Regular maintenance extends lifespan. Cleaning debris and checking fasteners improve performance. Many companies choose metal for its cost savings. Industrial roof fixtures explained in detail help businesses pick the best materials. A strong roof increases safety and efficiency. Always invest in high-quality roofing for lasting protection.

Built-up roofing (BUR) is strong and lasts a long time. It protects industrial buildings from heat, rain, and snow. This roofing has many layers of tar and gravel. These layers create a tough surface that stops leaks.

Industrial roof fixtures explained, BUR works well in large buildings. It holds up against heavy use and harsh weather. The gravel on top keeps the roof safe from the sun. This helps control indoor temperature.

Many factories and warehouses use BUR because it needs little upkeep. It also saves money over time. Workers can repair small cracks without replacing the whole roof. That makes it a smart choice for business owners.

Industrial roof fixtures explained, BUR is fire-resistant. That makes it safer than some other roofing types. It also works well with insulation, keeping buildings energy-efficient.

Choosing BUR for an industrial roof is a good decision. It lasts for decades and keeps buildings safe. Many industries trust it for strong and reliable protection.

Modified bitumen roofing offers strong and flexible protection. It combines asphalt with rubber or plastic. This creates a tough, waterproof surface. Many industrial buildings use this system for durability. In the U.S., nearly 35% of flat-roof buildings have modified bitumen. It lasts 20 to 30 years with proper care. Strong layers resist water, fire, and impact. Roofers install it using heat or cold adhesives. This ensures a tight, leak-proof seal. The surface reflects heat, reducing cooling costs. Factories, warehouses, and offices benefit from its strength. It handles foot traffic without damage. Regular maintenance prevents cracks and wear. Quick repairs extend its lifespan. Many companies choose this system for cost savings. Industrial roof fixtures explained in detail help businesses select the right materials. A strong roof boosts safety and efficiency. Always invest in high-quality roofing for long-term protection.

Choosing the right industrial roofing system needs careful planning. The roof must handle harsh weather. Strong materials increase durability. Many U.S. industries prefer metal, TPO, or modified bitumen. Over 50% of industrial buildings use metal for strength.

TPO roofing covers 40% of commercial spaces for energy savings. Modified bitumen works well for impact resistance. Cost plays a big role in decision-making. High-quality materials reduce future repair expenses. Energy efficiency also matters. Reflective roofs lower cooling costs by 25%. Installation time affects project deadlines.

Quick-to-install systems save labor costs. Maintenance needs vary by material. Low-maintenance roofs save money over time. Fire resistance ensures safety. Many industries require fire-rated roofing for protection. Leak prevention is another key factor. A strong seal stops water damage. Industrial roof fixtures explained in simple terms help businesses make the best choice. A well-built roof boosts efficiency and safety. Always choose quality for long-term benefits.

Single-ply roofing materials offer strong and lightweight protection. Many industrial buildings use them for energy savings. These roofs have one durable layer. TPO and EPDM are the most common types. In the U.S., over 40% of flat-roof buildings use TPO. EPDM covers nearly 25% of commercial roofs. Both materials resist water, heat, and UV rays.

TPO reflects sunlight, reducing cooling costs by 25%. EPDM handles extreme temperatures without damage. Roofers install these materials using glue, fasteners, or heat. This creates a tight, leak-proof seal. Single-ply roofs need little maintenance. Regular cleaning removes dirt and debris. Small repairs prevent major damage. Many industries choose this system for its low cost. Industrial roof fixtures explained in simple terms help businesses pick the best option. A strong roof boosts safety and efficiency. Always invest in quality materials for long-term protection.

Built-up roofing (BUR) offers strong and long-lasting protection. Many industrial buildings use this system for durability. It has multiple layers of asphalt and gravel. In the U.S., over 30% of flat-roof buildings use BUR. This system resists water, heat, and heavy foot traffic. Thick layers prevent leaks and damage. Proper installation ensures a tight seal. Regular maintenance extends its lifespan. BUR lasts 20 to 30 years with care. Many industries choose this system for cost savings. Industrial roof fixtures explained in simple terms help businesses pick the best materials. A strong roof improves safety and energy efficiency. Quality roofing protects investments.

A BUR roofing system offers strong and lasting protection. Many industrial buildings use this system for safety. Thick layers of asphalt and gravel create a tough shield. Over 30% of U.S. industrial buildings have BUR roofs. These roofs resist harsh weather, heavy rain, and strong winds. They last 20 to 30 years with regular care. Fire resistance adds extra safety. Gravel layers reflect sunlight and lower cooling costs. BUR roofs handle foot traffic without damage. Repairs are simple and affordable. Industrial roof fixtures explained help businesses choose the best options. A strong roof protects workers and equipment, reducing repair costs.

Modified bitumen roofing lasts long and protects buildings. Many U.S. industrial roofs use this system. Over 40% of flat roofs have this material. It resists heat, cold, and heavy rain. Thick layers prevent leaks and cracks. The strong surface handles foot traffic well. It works for warehouses, factories, and offices. Repairs are simple and low-cost. This roofing lowers energy bills by reflecting heat. Statistical USA-based information shows businesses save money with durable roofs. A good roof keeps buildings safe year-round.

Modified bitumen roofs last long and protect buildings. Many U.S. businesses choose this system. It resists harsh weather, heat, and heavy rain. Thick layers stop leaks and cracks. Strong material handles foot traffic well. Factories, offices, and warehouses use this roofing. Repairs cost less and take little time. Energy bills drop because the surface reflects heat. Statistical USA-based information shows durable roofs save businesses money. A good roof keeps buildings safe all year. Many companies trust this system for strong protection.

Metal roofing lasts long and protects buildings. Many industries use this strong roofing. It resists fire, wind, and heavy rain. Thick panels stop leaks and damage. Factories, warehouses, and offices use this system. Metal reflects heat and lowers cooling costs. Businesses save money on energy bills. Statistical USA-based information shows metal roofs last over 50 years. This system needs little maintenance. It handles snow, storms, and extreme heat. Many metal roofs use recycled materials. This makes them eco-friendly. Roof coatings stop rust and increase strength. Installation takes less time than other roofs. Many companies trust metal for safety.

Metal roofing lasts long and saves money. Many businesses use it for strong protection. It resists fire, wind, and heavy rain. Thick panels stop leaks and damage. This system works well for warehouses, factories, and offices. Statistical USA-based information shows metal roofs last over 50 years. They need little maintenance and handle extreme weather.

Metal reflects heat and lowers cooling costs. Many businesses save on energy bills. Recycled materials make it eco-friendly. Roof coatings stop rust and add strength. Installation takes less time than other roofs. Many companies trust metal for safety and durability.

Choosing the right industrial roofing needs careful planning. Climate affects roof durability. Hot areas need heat-resistant materials. Cold regions need strong insulation. Heavy rain needs waterproof layers. Statistical USA-based information shows climate impacts roof lifespan.

Building type also matters. Factories need fire-resistant roofs. Warehouses need strong support for heavy loads. Offices need good insulation. Each roof must match the building’s use.

Occupancy and operations affect choices. Buildings with heavy machinery need noise control. Chemical plants need roofs that resist corrosion. Storage facilities need temperature control. Roofs must fit business needs. A well-chosen roof saves money and lasts longer.

Roofcont helps businesses choose the best industrial roofing. Strong roofs protect buildings and lower costs. Statistical USA-based information shows durable roofs last longer. Weather, materials, and daily operations affect roof life. Our experts find the best solution for every project. We offer energy-efficient and weather-resistant options. Every business needs a roof that lasts. Call us today. Get expert advice and the best protection.

Deprecated: File Theme without comments.php is deprecated since version 3.0.0 with no alternative available. Please include a comments.php template in your theme. in /home/u737183660/domains/roofcont.com/public_html/blog/wp-includes/functions.php on line 6131